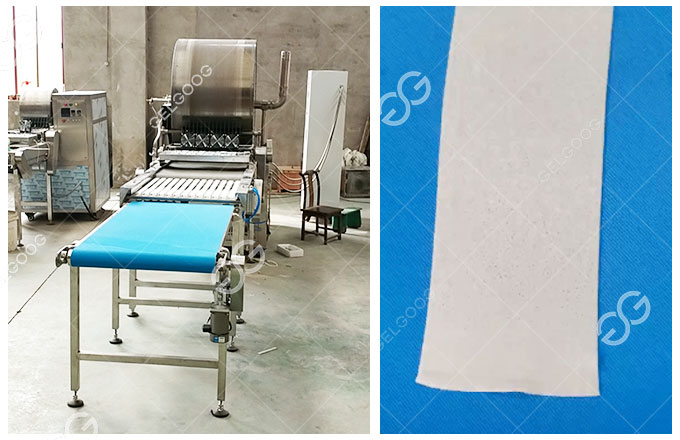

The spring roll wrapper maker machine is ideal equipment for producing high quality spring roll wrappers. It automates batter mixing, baking, cutting, cooling, stacking. The company can add freezer or packaging machine as needed.

For food processing factories planning to expand their spring roll wrapper production capacity, this equipment can increase output by 30%-40% in the same amount of time and require less manpower.

Main System of Spring Roll Wrapper Maker Machine

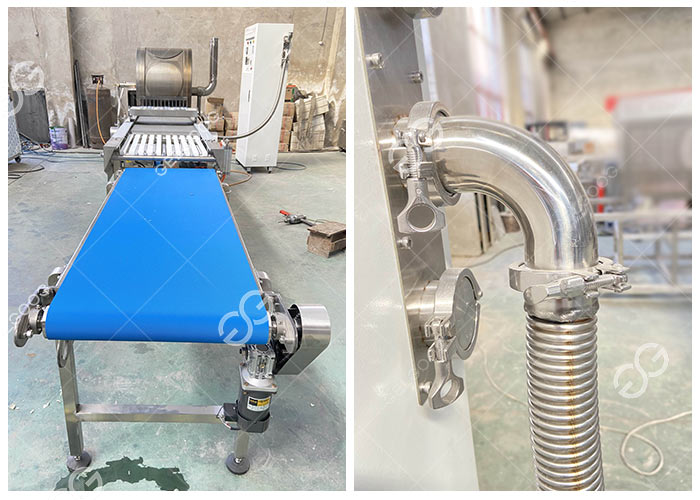

- Batter Mixing System: Evenly mixes flour, water, and other ingredients. The batter is then filtered through a strainer to ensure it is free of particles and impurities.

- Batter Spreading and Baking System: Evenly spreads the batter onto the heated rollers. Precise temperature control ensures uniform heating and a consistent color for the spring roll wrappers.

- Cutting and Forming System: Cuts the baked spring roll wrappers into standard sizes. You can produce spring roll wrappers of varying sizes to meet your needs.

- Cooling and Stacking System: Conveys and cools the finished spring roll wrappers, then counts and stacks them. This process continues for easy packaging.

Wide Application of the Spring Roll Wrapping Machine

The machine is very versatile. It can produce many kinds of thin pastry sheets. Common products include spring roll wrappers, samosa sheet, egg roll wrappers, etc. It can also make lumpia wrappers for Southeast Asian snacks.

Some users produce crepes or pancake with this machine. By adjusting temperature and thickness, you can make different styles easily. This flexibility makes it popular in food factories and restaurants.

Video of Machine to Make Spring Roll Wrappers

https://youtu.be/o8lrbLhqQrI?si=ahuc8BLE8bnEUOUl

Spring Roll Wrapper Maker Machine Price

The machine price depends on production capacity, heating method (electric or gas), and customization requirements. Entry-level models may start around USD 7,000–8,000, while fully automatic production lines can range from USD 15,000 to 30,000 or more.

While the initial machine investment may seem high, consider the long-term benefits, such as labor savings, increased production, and consistent spring roll wrapper quality. This makes it an affordable choice for most food manufacturers.

Where to Find Spring Roll Wrapper Machine for Sale

If you are searching for a spring roll wrapper machine for sale, GELGOOG is one of the reliable manufacturers providing professional solutions. The machines are exported to many countries in Asia, Europe, and North America.

A variety of models are available to match different production needs. Customers can select machines based on capacity, wrapper size, or automation level. GELGOOG also provides complete service support, including installation, training, and spare parts supply.

Frequently Asked Questions

- Can the spring roll wrapping machine make other wrappers?

Yes, with small adjustments, it can produce lumpia wrappers, samosa pastry sheets, and crepes. - What is the production capacity?

Depending on the model, the output can reach 5,00–10,000 pieces per hour. - How to maintain the machine?

Regular cleaning of the drum and cutting blades, as well as lubrication of moving parts, will ensure long-term performance.

Parámetros técnicos

| Modelo | GGSR-5029Y/F | GGSR-8045Y/F | GGSR-12060Y/F |

| Tensión | 380/220V(50/60HZ) | 380/220V(50/60HZ) | 380/220V(50/60HZ) |

| Potencia | 18kw | 40kw | 59kw |

| Potencia de acogida | 0,4 kW | 0,4 kW | 0,75 kW |

| Potencia de corte | 0,2 kW | 0,2 kW | 0,2 kW |

| Potencia de la cinta transportadora | 0,36 kW | 0,36 kW | 0,55 kw |

| Capacidad | 1000-1500pcs/h | 3500-4500pcs/h | 4500-7000pcs/h |

| Talla | 5200*950*1350mm | 6200*1100*1600mm | 6200*1300*2000mm |

| Peso neto | 520 kg | 1000kg | 1750kg |

| Thickness of Lumpia Wrapper | 0,3-2,0 mm | 0,3-2,0 mm | 0,3-2,0 mm |

Valoraciones

Aún no hay valoraciones.